Rapid prototyping and point of care 3D-print manufacture of patient-specific ostomy seal device

Industry partner

Singular Health

Research organisation

CSIRO

Manufacturing investment

$410,400

($98,639 IMCRC)

for 2021-22

Enabling personalised healthcare

Challenge

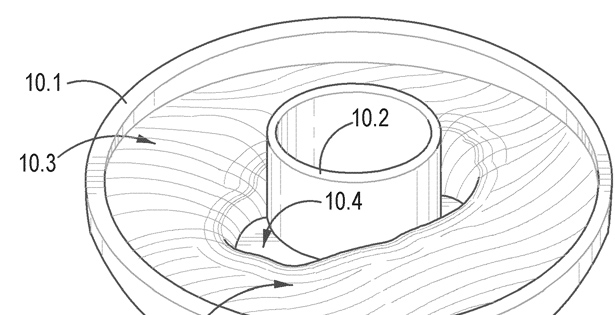

Medial technology company, Singular Health offers patients and practitioners’ access to personalised medical treatment options. In a pilot trial, using additive manufacturing technology, the company has successfully 3d-printed a customised ostomy seal – a medical device that creates a perfect seal between a patient’s abdomen and stoma bag, reducing the risk of leakage. To effectively commercialise the product, Singular Health seeks to optimise the seal’s production workflow – from scanning to surgery – which is currently disjointed, complex and time consuming.

Proposed Solution

Singular Health has developed a software application called 3Dicom that supports the ‘Scan to Surgery’ workflow by bridging various siloed activities involved in patient-specific surgical planning. As part of this project and with the support of CSIRO, Singular Health will develop a ‘Surface scan to model’ extension that will add 3D visualisation capability to the software.

By being able to visualise and process surface scans, in this instance, the topography of the stoma and surrounding abdominal area, will allow Singular Health to streamline the design and additive manufacturing workflow for the ostomy seal. The aim of the project is to substantially reduce the processing time from scanning to production, ultimately being able to commence 3D printing of the medical device in under 60 minutes.