SiC diode manufacturability and characterisation for commercialisation

Industry partner

Questsemi

Semefab Scotland

Research organisation

Griffith University

Manufacturing investment

$1,553,549

($143,701 IMCRC)

for 2021-22

The switch for energy efficient technology

Challenge

Silicon carbide (SiC) Schottky diodes are small semiconductor devices used in many power conversion systems. Due to their incredible thermal conductivity, high switching performance and efficiency, they are highly sought-after for applications such as solar inverters, motor drives and electric vehicle (EV) chargers. Yet, manufacturing SiC Schotty diodes is complex and generally associated with high capital investment.

Proposed Solution

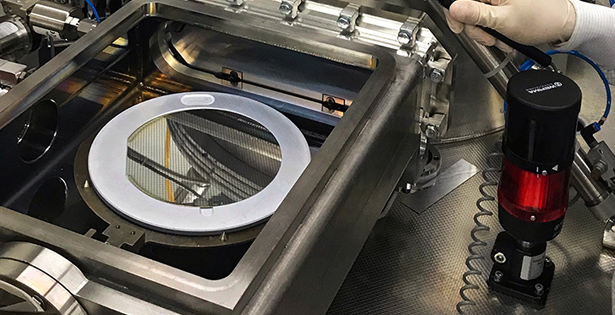

Queensland Semiconductor Technology Pty Ltd (Questsemi) has partnered with Griffith University to establish the manufacturability, performance, and characterisation of SiC Schottky diodes at a wafer level.

Researchers at the Queensland Microtechnology Facility (QMF) of Queensland Micro- and Nanotechnology Centre (QMNC) at Griffith University have developed a new technology that follows the same steps used in standard Si wafer processing, making the manufacturing process of SiC Schottky diodes much simpler and more cost-effective. As part of the 12-months project, they will set up a pilot production facility to test the performance of the technology and facilitate early production runs. The aim of the project is to fast-tack the commercialisation of the technology and create new business opportunities.