New aluminium alloys to significantly improve performance of heat exchangers

Optimising heat exchange operations

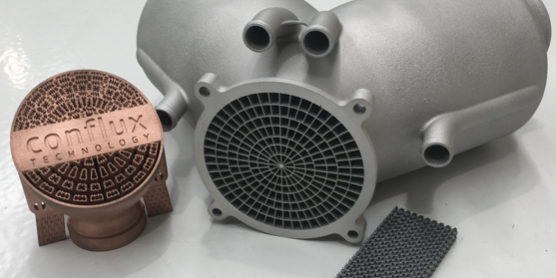

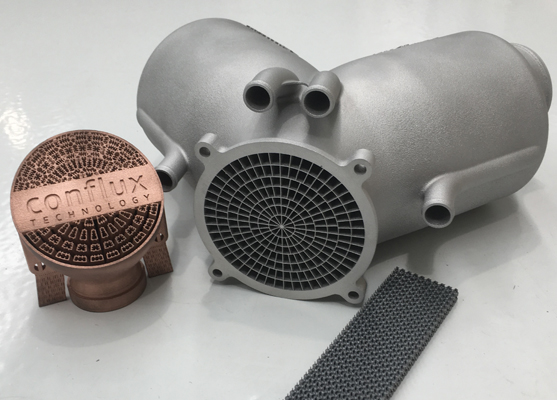

Leading additive manufacturing company Conflux Technology has joined forces with Deakin University’s School of Engineering and Institute for Frontier Materials (IFM) to develop new aluminium alloys for Conflux’s 3D-printed heat exchangers.

The 9-month research collaboration, which is supported by $138,000 in funding from the Innovative Manufacturing Cooperative Research Centre (IMCRC), will deliver alloys with enhanced material properties that optimise heat exchange operations.

Dr Matthew Young, IMCRC’s Manufacturing Innovation Manager, said the IMCRC activate project had the potential to catalyse significant advances in Australia’s additive manufacturing capabilities.

“Supporting novel alloy development specific to 3D printing processing conditions will maximise heat exchange efficiency, benefiting a number of sectors across Australia, from aerospace to energy. More broadly, it will enable an Australian manufacturing sovereign capability to produce products with improved performance, geometries and fabrication,” he said.

“As this project demonstrates, enabling research institutions and industry to build symbiotic relationships remains key to developing a world-leading Australian manufacturing industry.”