$2.57 million collaborative research project to commercialise zeolite process

IMCRC invests in research collaboration between Neometals Ltd (Neometals) and Queensland University of Technology (QUT) to set up synthetic zeolite manufacturing pilot plant.

Key points

- Neometals, QUT and IMCRC partner to accelerate the development of zeolite production in Australia

- Research project to explore digital manufacturing technologies and build a pilot plant for the conversion of lithium refinery residue (waste) into high-value, synthetic zeolites

- Zeolite manufacture from lithium refinery residue could eliminate waste disposal and associated costs from lithium production

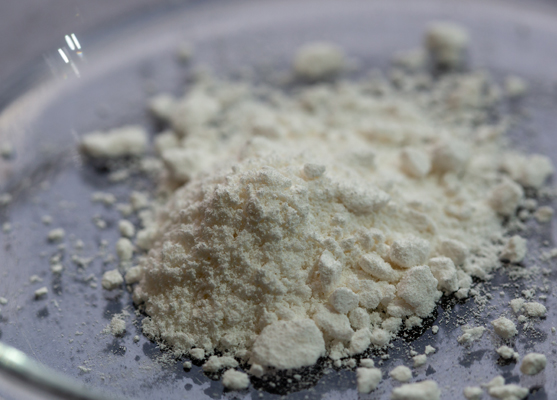

Perth based project development company, Neometals which has developed a patent pending process that converts aluminosilicate residue – a waste material produced when extracting lithium from ore concentrates – into an advanced material know as synthetic zeolites.

Zeolites are microporous, aluminosilicate minerals commonly used as molecular sieves, sorbents and catalysts in applications such as gas separation, water purification and green chemistry.

Managing Director of Neometals, Chris Reed, explained that their research has shown a gap in the market and high potential to add up-stream value to the lithium production chain.

“Australian mining companies involved in the lithium production chain have the opportunity to convert aluminosilicate residue to zeolites to off-set production costs, add value to a waste material which is abundant in the mining sector and at the same mitigate issues with environmental responsibility,” he said.

In partnership with QUT, Neometals plans to advance the proof-of-concept zeolite synthesis method which has been successfully demonstrated at bench scale.

Over the next two years, QUT will be establishing and road testing a digitalised pilot plant at their Banyo Pilot Plant facility. By championing “smart” manufacturing processes and incorporating advanced inline monitoring technologies, the pilot plant will be able to track the entire aluminosilicate minerals processing route – from its initial extraction to transforming it into high performing synthetic zeolite.

Professor Graeme J. Millar who will lead the QUT research team highlighted that the proof-of-concept had shown how a mining waste product otherwise destined for landfill can cost-effectively be repurposed.

“With the use of data analytics and machine learning, we can gather information that will allow us to set up operational control parameters to ensure that customer product requirements are met”, said Professor Millar.

“At the same time, the data will drive the optimisation of the plant performance, which will help Neometals to explore innovative business models to compete on a global scale.”

The $2.57 million research project includes $450,000 of matched funding from IMCRC and Neometals to introduce digitalisation into mineral processing plants. The project is due to start in February 2020.

David Chuter, IMCRC CEO and Managing Director, pointed out that Neometals is in a unique position to add up-stream value to Australia’s lithium mining sector.

“By taking a proactive and innovative approach to dealing with waste from their Lithium Refinery, Neometals has developed and proven a new process to produce high value synthetic Zeolite which will allow the organisation to extend their reach and secure new market opportunities”, said Chuter.

“The project, by integrating new digital manufacturing processes and capabilities, will enable Neometals to test all production parameters and upscale manufacturing to an economic industrial scale.”