Pilot manufacturing plant to produce high-purity alumina for batteries and LEDs

QUT researchers have partnered with mining company Lava Blue and the Innovative Manufacturing CRC (IMCRC) to set up a pilot plant to transform kaolin clay into high-purity alumina (HPA) which is used to make LEDs and Lithium ion batteries.

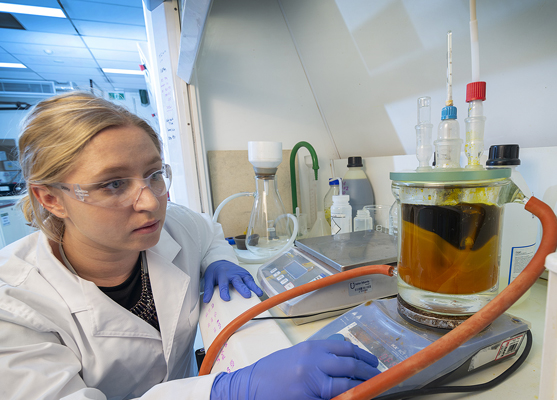

Project leader Dr Sara Couperthwaite said the two-year pilot plant study, to be built at QUT’s Banyo Pilot Plant facility, aimed to show that the process had better economic and environmental outcomes than conventional production routes.

Kaolin is an abundant natural clay resource. High-quality kaolin is used in the manufacture of paper, porcelain, toothpaste and antacids.

Lava Blue discovered a large resource of kaolin suitable for refining into 99.99 per cent pure HPA while mining its Lava Plains property in North Queensland for cobalt blue sapphire.

Lava Blue managing director Michael McCann said Australia was in a prime position to be one of the world’s major suppliers of HPA.

“Because HPA is presently made by starting with high-purity aluminium metal, it is quite an expensive material,” Mr McCann said.

“A cheaper path to production of HPA from kaolin has been demonstrated in the laboratory but has not previously been scaled up to an economic industrial scale.

“The Lava Blue HPA project will erode the technical risks of scaling up HPA production from kaolin, while developing advanced controls that will deliver the critical quality control required for this high purity, specialised product.”

Dr Couperthwaite said in the past year, the research team had demonstrated the process could produce HPA at laboratory scale by understanding the process from both science and engineering perspectives.

The pilot plant will involve innovative manufacturing processes with advanced inline monitoring technologies that will enable the single system to produce different HPA products for a range of commercial products.

The pilot plant will be extracting the aluminium content of a low quality kaolin clay with no other commercial value, and transforming it into the high-value commodity HPA.

The process of leaching the clay to produce HPA offers a simple alternative to the current industry model of producing HPA, which presently involves a chain of production processes across different industries.

HPA is used in the production of ceramic-coated separators (CCS) that separate the anode and the cathode in lithium ion and other high-energy density batteries, improving their safety and performance.

These types of batteries are employed in everything from mobile phones and power tools to electric cars and for electricity storage systems.

“The Lava Blue process is very versatile and we can utilise machine learning and artificial intelligence to make tailored HPA products from the same processing plant with slight adjustments in the process chemistry,” Dr Couperthwaite said.

The $4.45 million project includes $645,000 of matched funding from IMCRC and Lava Blue to make advancements in using smart technologies in mineral processing plants.

“This research grant enables us to develop a manufacturing process and pilot plant that is capable of collecting large quantities of real-time data that can be data mined and used to enhance the performance of the process,” Dr Couperthwaite said.

IMCRC CEO and Managing Director David Chuter said that smart technologies would be the catalyst for moving beyond traditional mineral extraction and processing, creating a production industry within Australia’s resource sector.

“Australia has unmatched scale and quality of valuable natural resources,” Mr Chuter said.

“Now is the time to capitalise on this competitive advantage by using industry-led research collaborations to explore emerging technologies that allow Australian businesses such as Lava Blue to diversify into new manufacturing opportunities and value chains.”