Composites and Industry 4.0 combined in Paris

Composite materials are rapidly becoming a mainstream technology and materials of choice within many industries. Matthew Young travelled to Paris to check out the latest trends and developments at JEC World 2018.

From the 5th to the 9th of March I visited Paris to look at latest advances in Composites Materials and Industry 4.0. Included in the visit were two side trips to Dassault Systemes “3DS Campus” and BeAM Machines in Strasbourg (Manufacturer of Direct Energy Deposition Metal Additive Manufacturing Machines).

JEC World is Composites Industries largest trade show, 2018 saw more than 1300 exhibitors (Which Included IMCRC Participant Deakin Universities / Carbon Nexus) with 42,445 visitors from 115 countries being recorded. This year’s show had automation at the forefront and the Automotive sector push for e-mobility the primary target audience for many producers displays. Fully functioning automated composites manufacturing lines, (lay-up, cure and trim), were numerously featured with the VOITH display a clear standout, featuring the Audi A8’s carbon fibre back panel and parcel shelf which is in production today after a 6 years development partnership.

“I just want to say one word, Just one word to you: Thermoplastics”. Yes, this is a misquote from The Graduate; but it clearly is the current focus material for both Automotive and Aerospace manufactures as an enabler to lower cost automated production of lightweight composite products. SABIC and Airborne, “powered by Siemens”, presented “The Digital Composites Manufacturing Line”: a fully automated and digital process that allows the production of thermoplastic composite laminates in large scale. Covestro launched a range of continuous carbon fibre reinforced polycarbonates for use in consumer product housing (smart phone, laptops, tablet and even air-conditioning casings) as a “tougher and more durable” alternative to existing materials. This places Covestro as an early mover in the continuous fibre thermoplastics materials supply space for consumer products.

During JEC World IMCRC partners Swinburne University of Technology publically announced the establishment of world first Industry 4.0 Testlab for carbon composite manufacture based on process equipment developed by Austrian engineering companies FILL, who actively exhibited their products throughout the 3-day event. The centrepiece of this testbed is an industrial scale 3D printing “multilayer” tape laying machine for continuously reinforced thermoplastic and thermoset. Being the first of its kind in the world this will position Swinburne University of Technology and their industry partners at the forefront of high volume production, composites automation and industry 4.0 in Australian.

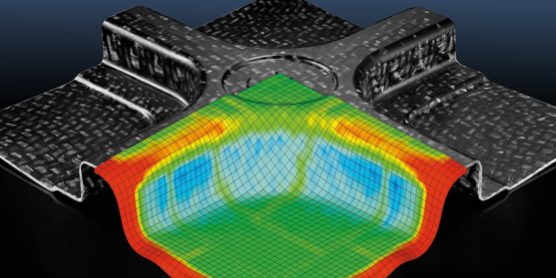

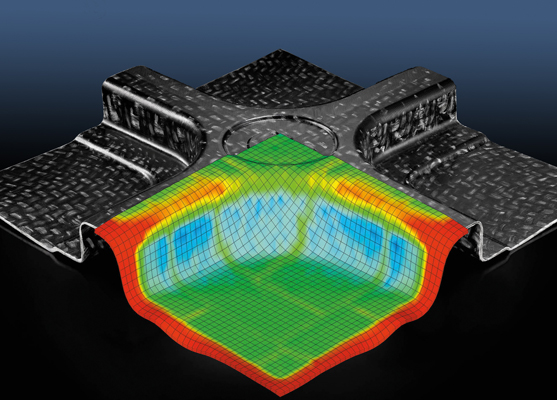

The side trips to Dassualt Systemes and BeAM were eye openers to the development of Digital Manufacturing and Collaboration models. At Dassult Systemes I was provided with an overview of current capabilities of DELMIA and its digital simulation of production processes. This included a VR tour of an automotive seat production line as a complete “digital twin”. BeAM provided a comprehensive overview of their Direct Energy Deposition Metal Additive Manufacturing Machines and capabilities which has been primarily developed over a short commercial timeframe of 3 years. Key to the development of these machines has been an “Open Innovation Network” which provides complete knowledge transfer to partners, (both Universities and Industries), to become regional experts in the technology and to collectively enhance the technology and range of applications. Such Open Innovation Networks could be of great benefit to similar undertakings in Australia for manufacturing equipment and process development.

Although Maurice Chevalier famously sang “I love Paris in the Springtime”, I could not validate this observation with data collected during this visit, thanks to the hang over from the “beast from the east” the entire week was damp and cold, and to top this off I returned with a nasty dose of the Flu. Clearly, I concluded further data and analysis will be required to validate the lyrics of this song.

If anyone would like more background from this trip or insights to Composites and Industry 4.0 please don’t hesitate to contact me by phone, email or in person…..as my Flu is no longer contagious.

Matthew Young