Thales Australia

Development of lightweight Australian composite overwrapped gun barrels

Research partner

Deakin University

Total Project Value (AUD)

$279,352

IMCRC Funding (AUD)

$51,567

Start date

07/02/2022

Duration

6 months

Material made from carbon fibres is incredibly strong and light, making it an ideal replacement for steel or plastic when manufacturing next-generation weapons.

However, the fibres aren’t currently made in Australia and procuring them from international suppliers can be difficult due to export restrictions and supply chain disruptions.

In 2021, these factors motivated leading defence contractor Thales Australia to partner with Deakin University on a 6-month, $234,000 research and development (R&D) project.

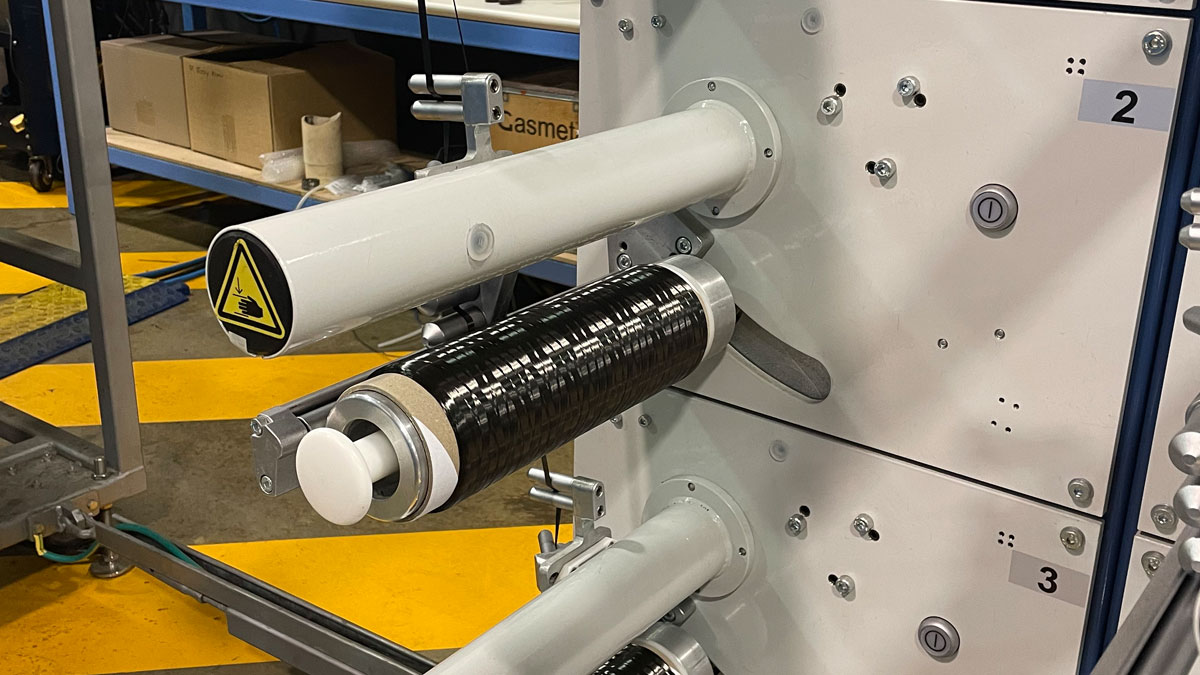

The project focused on developing Australian-manufactured intermediate modulus carbon fibres for use in civil gun barrels. The novel fibres form an overwrap for the barrel, reducing its thickness and enabling Thales to deliver a lighter, more precise product.

Gabriel Gudas, Manufacturing Technology Manager, Integrated Weapons and Sensors at Thales, said the product had already garnered significant interest from industry, other composite experts and customers across the globe.

“It’s a very topical R&D project. We’re currently qualifying the product and are planning to manufacture over 1000 units for commercial use in 2023,” he said.

“In addition to developing the fibres, one of the main benefits has been the specialised training in composite manufacturing that Deakin provided to our staff from the Lithgow Arms Facility. We’ve successfully developed a composite demonstrator and our staff now have the skills to support the ongoing manufacture of carbon fibres.

“The research expertise Thales has seen and supported at Deakin is a great indicator of what’s possible in Australia. Our industry is growing, and Australia has to be part of it.”

Gudas said in addition to the funding, a key benefit of the collaboration was the critical guidance IMCRC provided at every stage.

“IMCRC’s project management structure promoted collaboration, ensured we met our milestones and, I believe, delivered a better outcome as a result,” he said.

Prof Russell Varley, Professor of Composite Materials at Deakin University, said the team at Carbon Nexus was grateful for the opportunity to partner with Thales and IMCRC.

“This collaboration enabled us to develop a completely novel intermediate modulus fibre. The knowledge we’ve honed has expanded our skill set and manufacturing capital, and Carbon Nexus is now looking to see how we can fulfill the demand for low-volume manufacture of bespoke carbon fibre.” he said.

The opportunity to finance the project with the help of MCRC was an opportunity that couldn’t be missed. We’re incredibly pleased we decided to develop and commercialise an Australian-made material of the future.

Gabriel Gudas

Manufacturing Technology Manager,

Integrated Weapons and Sensor, Thales Australia