Mineral Technologies

Revolutionising mineral separation using additive manufacturing

Research partner

UTS

Total Project Value (AUD)

$9,309,045

IMCRC Funding (AUD)

$1,800,000

Start date

01/04/2018

Duration

4.5 years

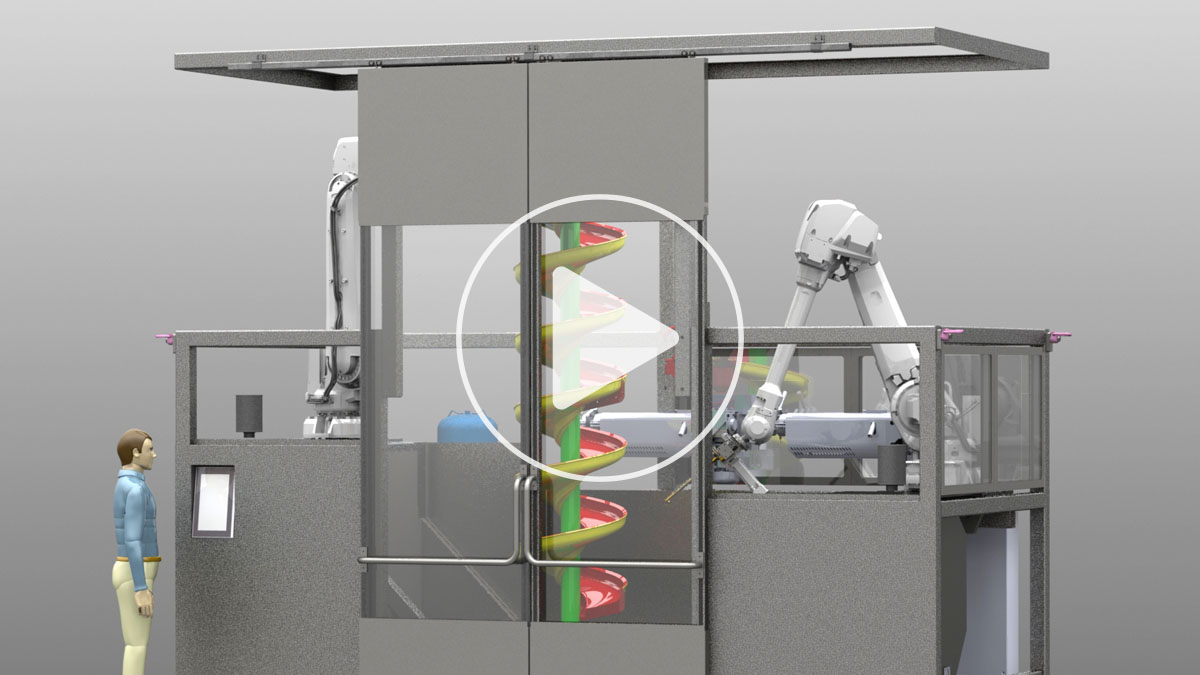

Currently, gravity concentrators (also known as spirals) are cumbersome and capital intensive to manufacture, often exposing operators to chemicals and other hazards.

In 2018, Mineral Technologies, a Downer Company, partnered with IMCRC and the University of Technology Sydney (UTS) to research solutions that will revolutionise how composite polymers are used to manufacture precision-engineered mineral separation equipment and other mining components, using additive manufacturing.

According to Mineral Technologies General Manager Alex de Andrade, as the project progressed, it became clear that additive manufacturing consumables had a substantially higher cost than the traditional spraying and casting polyurethane methods.

“We currently produce more than 600 containers a year filled with similar products, which customers then ship all over the world from Australia, creating a huge CO2 carbon footprint by burning fuel in transit. By converting the production cell (printer) to something that can travel, this will allow us to have 10 or 20 printers traveling a year rather than 600 containers. It is important to us to consider not just the cost of manufacturing the product but look holistically, from order to commissioning costs and the savings on the environment that our customers can benefit from when adopting this technology.”

De Andrade said that while Mineral Technologies has had many years of experience working with universities on research and development projects, he was impressed by the level of collaboration, respect and dedication to this project’s end goal.

“We went through some difficult lockdowns and experienced delays on critical imported parts, but the UTS and IMCRC teams had a lot of mutual respect and understanding. The contribution from UTS has been equal to that of Mineral Technologies, as if they were in the business and it was as important for them as it was for us.

“IMCRC also helped us as a business understand and determine our technology roadmap and directive by setting a business vision for collaboration, advanced manufacturing and IoT adoption. The CRC’s early guidance and stage gates for the project allowed us to fail safe. Their networking advice and introductions to other businesses also meant we were able to make industry connections that would not have been possible on our own.”

There’s a lot of respect, trust and belief amongst the collaborative design team in delivering this project successfully. We collectively believe in the outcome for the greater good of this environmentally sustainable mobile manufacturing technology.

Alex de Andrade

General Manager of Mineral Technologies