Australian Red Cross Lifeblood

Design and development of a work cell for robotic folding of whole blood donation packs

Research partner

Swinburne University of Technology

Total Project Value (AUD)

$423,214

IMCRC Funding (AUD)

$79,104

Start date

01/02/2021

Duration

1.4 years

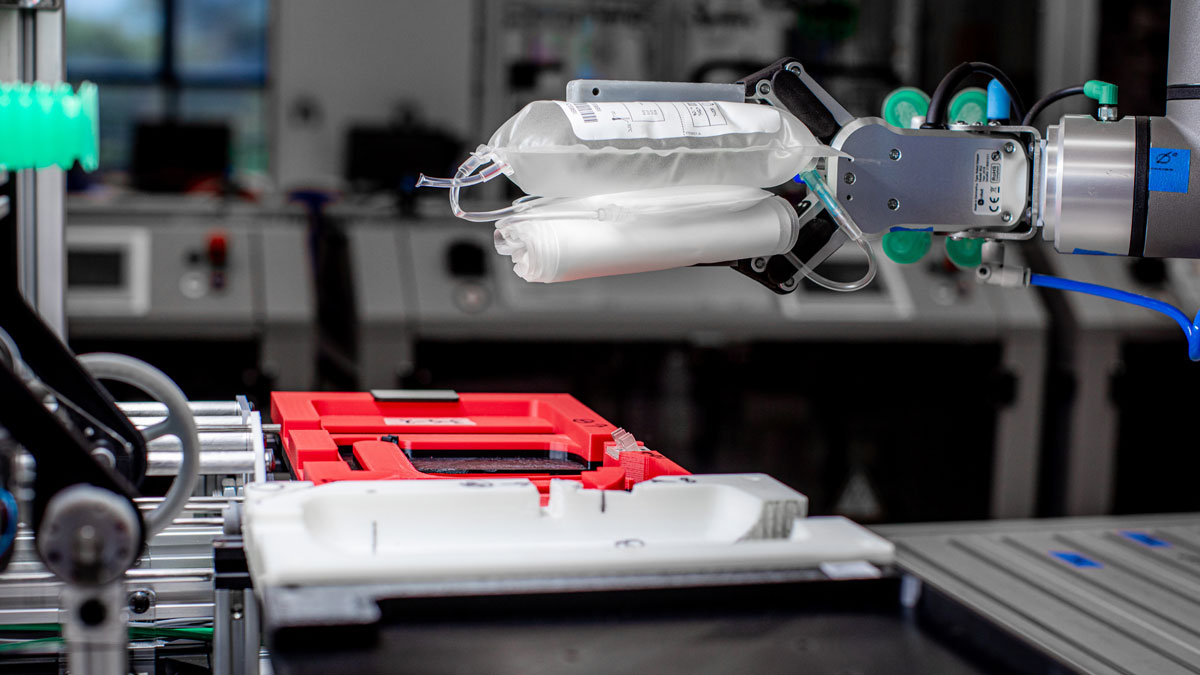

Currently, processing blood donations is a complex, manual task. At processing centres, staff fold the blood packs by hand so the blood can be centrifuged and thus separated into its cellular components.

Despite rigorous training, there is the potential for human error throughout this process, and staff face risks including repetitive strain injury and exposure to potentially hazardous biological materials.

That’s why in 2021, Swinburne University of Technology partnered with IMCRC on an 18-month research collaboration to develop a world-first system capable of handling and folding blood packs.

In addition to addressing risks to staff, the project sought to minimise disruptions to production, reduce deviations in quality and enable the capture of operational data – which is needed to meet regulatory process monitoring requirements.

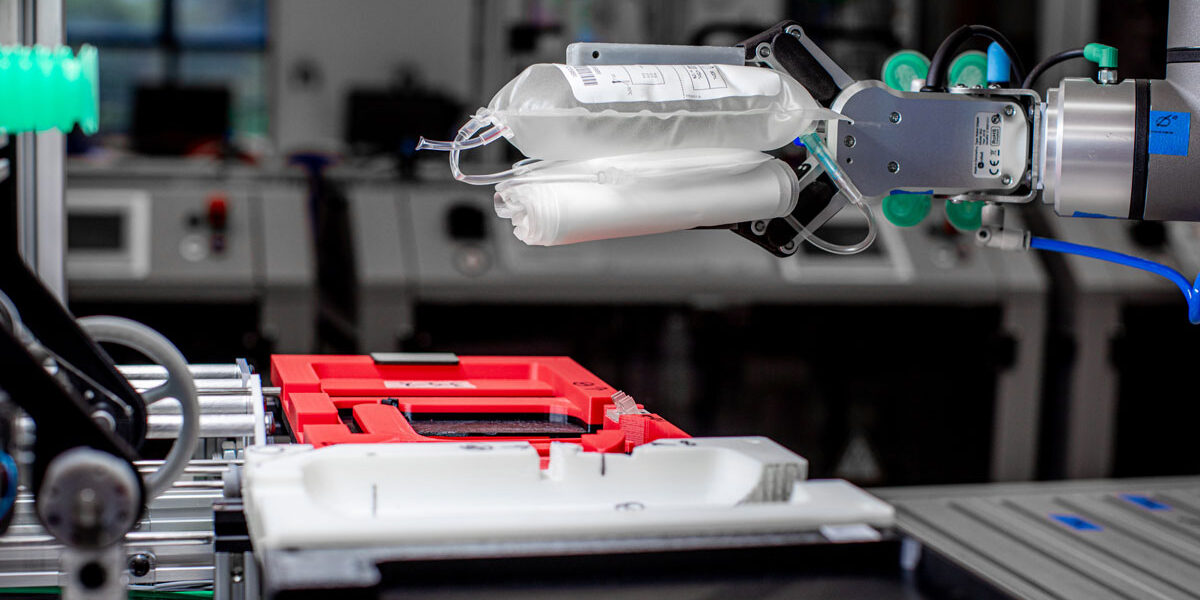

By utilising collaborative robots, vision systems, jigs and actuators, the project – which concluded in July 2022 – has successfully delivered a proof-of-concept prototype capable of folding the soft, deformable blood packs.

Project Champion and Scientific Director, Manufacturing and Quality at Australian Red Cross Lifeblood Sue Ismay credits the success of the project to the fact a domain expert from Lifeblood was embedded into the project team at the Factory of the Future at Swinburne’s Hawthorn Campus.

“The Lifeblood expert was able to advise the researchers about every aspect of the blood pack handling process, and their presence created an inclusive environment where issues could be addressed on the spot,” she said.

“The research collaboration benefited from this in multiple ways, as there was a shared understanding of core processes and associated risks and obligations. Feedback could also be provided, applied and tested in real-time.”

Deputy Director of Swinburne’s Factory of the Future Dr Shanti Krishnan said IMCRC’s clear processes kept the project on track, especially through delays caused by the pandemic.

“IMCRC’s stage-gated approach measured our progress against clear milestones, which helped mitigate the risk of the project and ensured all partners were aligned,” said Dr Krishnan.

“As it moves towards commercialisation, our prototype has the potential to transform a critical manufacturing process for the global medical industry. And the effective integration between all partners was key to achieving this outcome.

“IMCRC has been instrumental in bringing this project to life. The team has been with us every step of the way, from helping us refine the initial project proposal to challenging and questioning our approach to ensure it was robust.”

IMCRC has been instrumental in bringing this project to life. The team has been with us every step of the way, from helping us refine the initial project proposal to challenging and questioning our approach to ensure it was robust.

Dr Shanti Krishnan

Deputy Director, Swinburne Factory of the Future