FormFlow

Industry 4.0 enabled manufacturing cell for building products

Research partner

Deakin University

Total Project Value (AUD)

$548,294

IMCRC Funding (AUD)

$103,498

Start date

01/11/2020

Duration

1.5 years

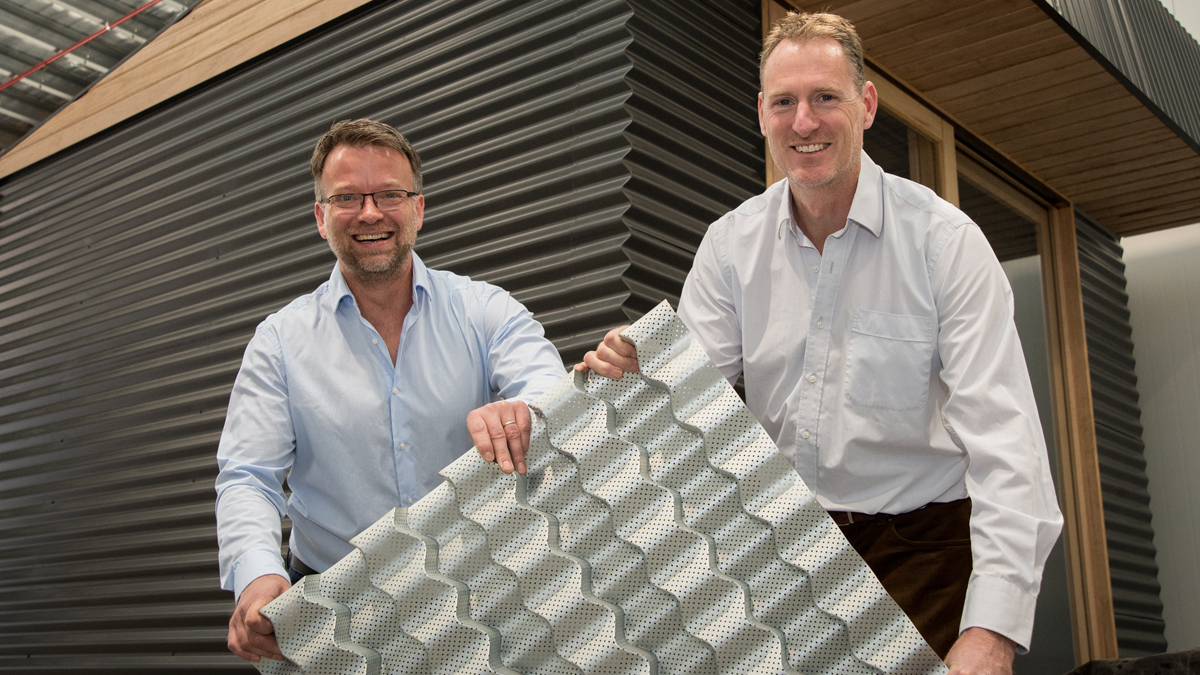

In 2021, Geelong-based manufacturing start-up FormFlow partnered with Deakin University to develop an Industry 4.0 enabled manufacturing cell to optimise and upscale its production capability.

“The scrap rate in the steel manufacturing industry can be as high as 6%,” said Dr Matthew Dingle, FormFlow’s Managing Director. “One of our motivations was reducing waste by gaining greater oversight into the process monitoring and control of steel forming operations.”

With a total project investment of around $1 million catalysed by IMCRC, the 12-month project began by exploring the use of smart vision technologies to trace, evaluate, and monitor forming loads and the profile shape of corrugated steel before and after bending in FormFlow’s process.

According to Matthias Weiss, Senior Research Fellow at Deakin University, as the project progressed, it became clear the fundamental research into the solution could inform different directions which would deliver greater efficiencies.

“IMCRC is incredibly committed to delivering real world outcomes for industry. When we approached them with a request to adjust the scope of the project and articulated the benefits for FormFlow and the broader industry, IMCRC approved it straight away. Because of this flexibility, we were able to realise unexpected – but fantastic – commercial outcomes. It’s been one of the most successful and fulfilling projects that we have participated in,” he said.

Matthew added, “By facilitating a change in scope, IMCRC supported two new FormFlow innovations: a 2D laser system that enables the manufacturer to perform continuous, real-time quality control and an Industry 4.0 manufacturing cell capable of producing a corrugated corner bend from a flat sheet of steel.”

“We’ve already had significant interest in both products, and the research has also helped to expand other areas of FormFlow’s business. It’s been a fantastic project. We’ve met all the milestones we expected to meet and more, in part due to the support and dedication of IMCRC’s team.”

It’s been a fantastic project. We’ve met all the milestones we expected to meet and more, in part due to the support and dedication of IMCRC’s team.

Dr Matthew Dingle

Managing Director, FormFlow