3D printing to thrive during COVID-19 and beyond

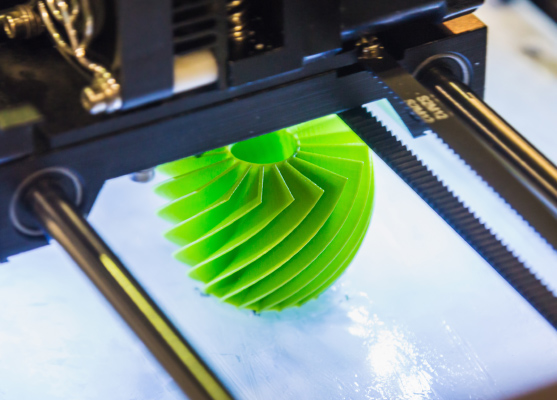

It is a common belief that you can make almost anything you want when it comes to 3D printing.

Bits and pieces ranging from a splint for a broken arm, a bulldozer part that has split or cracked, to a malfunctioning part on a navy ship patrolling high seas in the Middle East, can be remade with relative ease compared to a traditional replacement.

The 3D printing process, also known as additive manufacturing, is currently being adopted to solve some of Australia’s supply shortages during COVID-19.

Industry organisations such as the Innovative Manufacturing CRC (IMCRC), CSIRO and industrial-scale additive manufacturing company Titomic are at the forefront of promoting 3D printing technologies and advocating for its growth.

IMCRC CEO David Chuter said 3D printing, particularly for plastics, has never been more relevant.

“I think there’s a much greater awareness, certainly in the media, of many companies who are mobilising for help with very quick manufacturing of products in Australia that would not be possible without 3D printing,” he said.

“The ability to have 3D printing means you can respond to manufacturing needs in very short-term time frames.”

The ability to 3D-print unique products for customers in real time such as hospitals to support health care and making bottle tops for hand sanitiser has been provided “huge opportunity” for competition in the domestic market, according to Chuter.

“The challenge in the plastics space is to make a traditional injection mould tool takes several weeks of design and manufacture before you can your first part,” he said.

“You can make one part, refine the design, make the second part and really optimise the design very, very quickly to get products into market, and that’s been really under the spotlight in terms of responding to the COVID-19 crisis.”